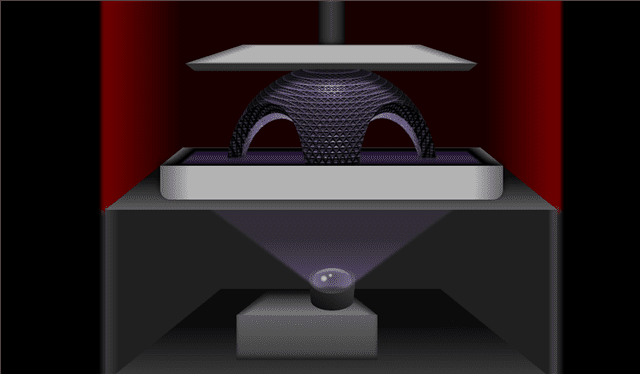

3D printing has undergone many evolutions in recent years and is now more accessible than ever. One of the drivers of this accessibility is the use of DLP technology in 3D printers. DLP 3D printers use light projected into liquid resin and other substrates. The light cures the substrate as it is projected, leaving you with a final 3D piece of solidified material.

Accessible and Affordable Desktop 3D Printing

DLP Technology is the perfect solution for an accessible and affordable 3D printer that can fit right on your desk – just check out the AnyCubic Photon Ultra that’s launching via Kickstarter! Despite the small size of these printers, their DLP chipsets deliver faster printing speeds, greater print detail and are more reliable than alternative 3D print technologies thanks to their advanced image processing and superior resolution.

Here are some considerations for DLP 3D printing systems to give you the best prints possible:

Choosing a Chipset for Your DLP 3D Printer

DLP Technology was originally designed for display applications rather than light control. While these display chipsets have decades of research and development behind them to optimize display and projection of movies and images, these chips are not designed for 3D printing.

The superior alternative would be light control chipsets. Unlike display chipsets, they are designed to work across virtually the entire light spectrum, from UV to visible to near-infrared, to project structured light patterns to ensure accurate printing. They utilize dithering and image processing to ensure the printed object matches the input data.

Processing Layer Slices for the Best Surface Finish

One of the benefits of DLP Technology is that it projects optically focused light, which allows it to focus on the resin and print a single layer at a time. This gives you excellent resolution with pixels that won’t blur as well as faster production time.

One issue you can run into with 3D printing is that the printing substrate can absorb light energy in a way that creates boxy pixels – not good for a smooth finish! Using grayscale structured light patterns can eliminate this and create the smooth surface finish that you’re looking for.

Determining the Highest Resolution for Your 3D Print

With DLP Technology, higher resolution means a smoother surface finish and the ability to add super fine details. With optimization of DLP 3D printing technology, you can take advantage of it’s high switching speed and efficiency to expand the resolution from 0.9 megapixels to 3.6 megapixels.

As demand for 3D printing grows, we need affordable and accessible printing solutions that are quick, reliable, accurate, and precise.

TI DLP chipsets have enabled powerful, flexible, and programmable light control solutions for your 3D printing. The DLP300S and DLP301S from Texas Instruments project quadruple the number of pixels on the resin, which increases build size, resolution density, or both. Check out the models for DLP300S and DLP301S, and learn more about considerations for DLP 3D printing systems from Texas Instruments.