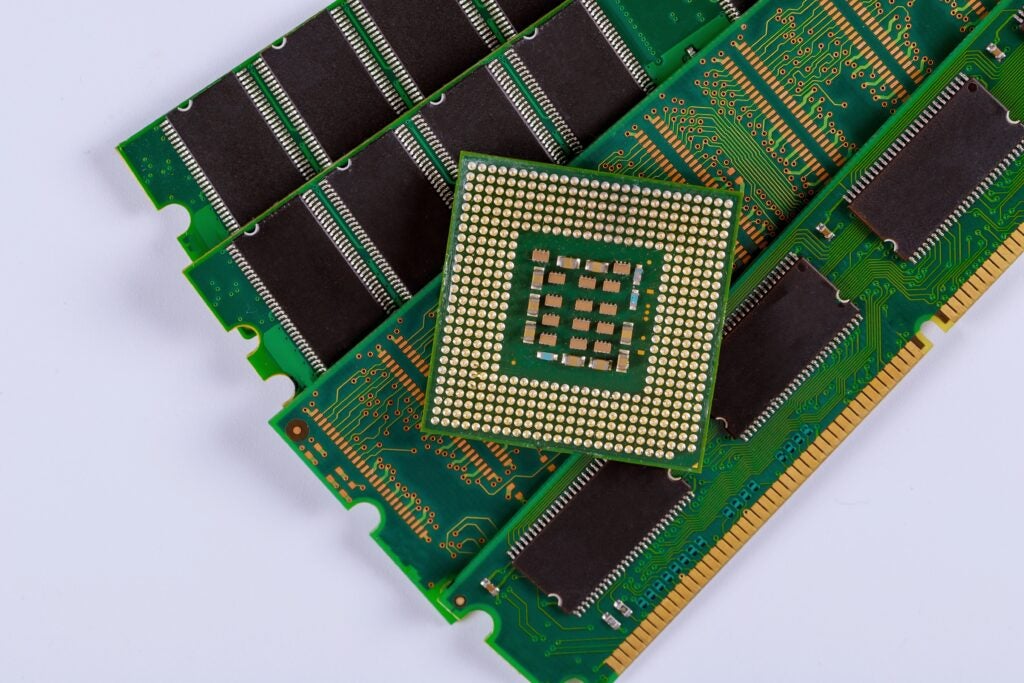

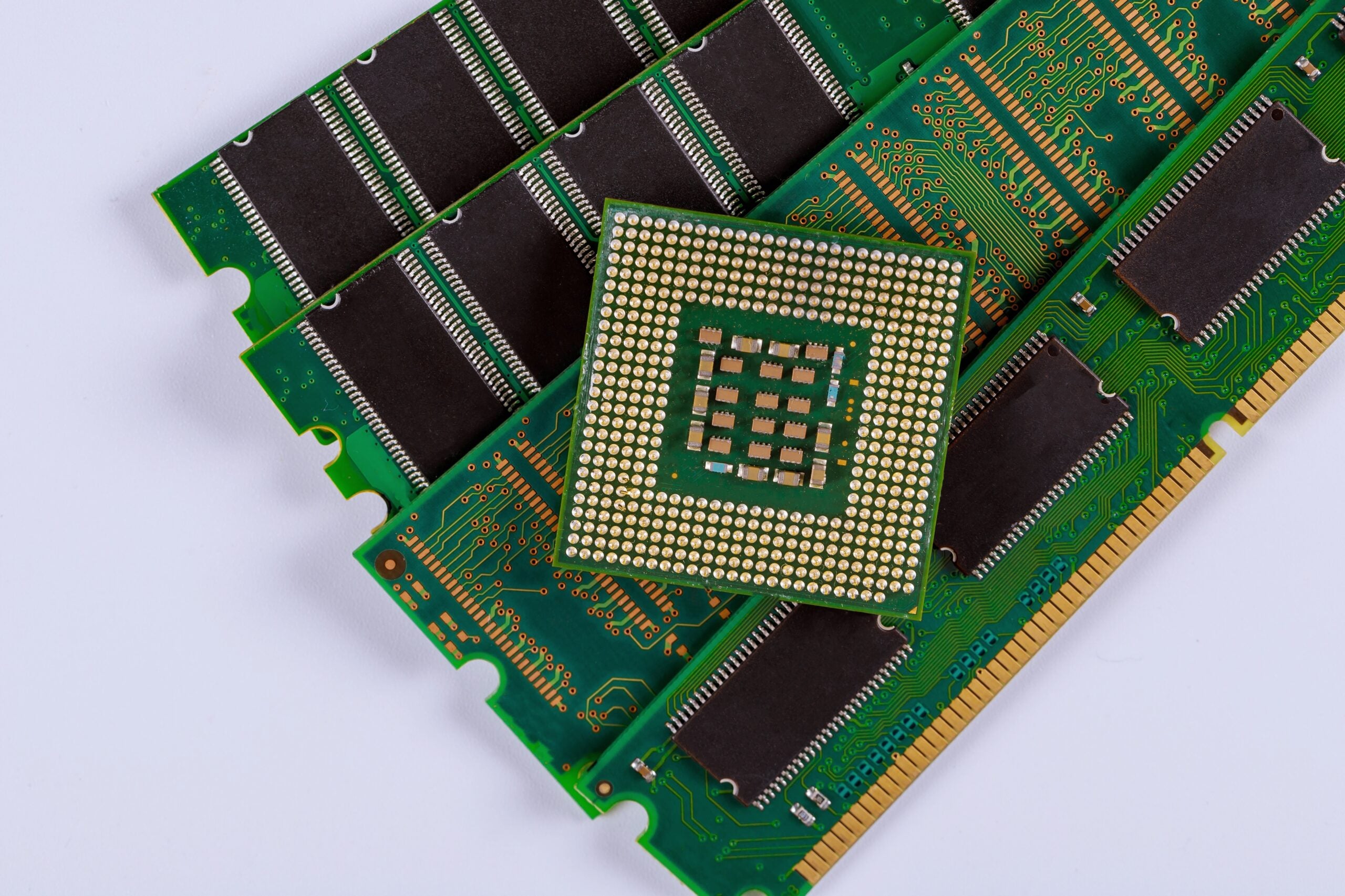

Microprocessors (MPUs) and certain memory chips continue to drive the electronic component shortage in 2025.

Whenever someone begins a sentence with “Believe it or not,” I expect to be treated to an outlandish claim of some sort. Well, here goes: Believe it or not, there was actually an excess supply of electronic components in 2023. This abundance, which did not extend to specialized and/or critical components for more complex systems, was due in part to original equipment manufacturers (OEMs), contract manufacturers (CMs), and electronics distributors adopting inventory management practices like bulk purchasing and stockpiling to counteract the manufacturing and trade interruptions initiated in response to the COVID-19 pandemic.

Unfortunately, many causes of supply chain disruption persist. Resulting in shortages of microprocessors, high-end memory chips, and other semiconductor-dependent components that are critical for building products like automotive systems. However, an understanding of the causes and effects, coupled with a good mitigation strategy and the best inventory management software, are the keys to surviving the electronic component shortage of 2025.

Surviving the Electronic Component Shortage of 2025

The technological advancements of the past few decades have been driven by continual innovations in software and hardware tools to better implement and utilize previously discovered theories and principles. For example, semiconductive properties were first observed by Michael Faraday in 1833, the transistor was invented in 1947, and the first integrated circuit appeared in 1958. However, it took the development and evolution of design software and manufacturing hardware to create and implement the semiconductor-based electronic devices we rely on today, including mobile phones, computers, medical devices, smart appliances, automotive, and aerospace systems.

Our reliance on these products is undeniable, and it is imperative that the electronic and electromechanical components that compose them are readily available. However, availability and component lead times continue to be persistent issues for the electronics industry, and the electronic component shortage of 2025 is expected to be an even greater challenge than in recent years. This is due to both commonly known and new factors to contend with. Successfully addressing these requires developing and implementing a well-defined set of guidelines, as listed below.

| GUIDE TO ELECTRONIC COMPONENT SHORTAGE 2025 SURVIVAL | ||

| Order | Guideline | Benefits |

| 1 | Understand component shortage trends . | Accurate, up-to-date information allows you to make the best predictive decisions about component availability and costs. |

| 2 | Understand the causes of your component shortage. | Knowing the specific electronic component shortage factors that are impacting you directly allows you to develop the best strategy and choose the best tool for your design and development. |

| 3 | Prioritize component data management . | Access to accurate, manufacturer-supplied, or vetted CAD models and data is critical to make informed decisions and take appropriate action to mitigate the effects of shortages. |

| 4 | Prioritize supply chain resilience . | Ensures a more efficient design, component procurement, and board manufacturing workflow. |

| 5 | Implement a supplier mapping strategy . | Streamlines component selection and procurement processes. |

| 6 | Implement inventory management software . | Helps automate component selection/creation, supports supply chain resilience, and lowers design and development costs. |

As shown above, there are three key attributes for a successful electronic component shortage 2025 mitigation plan: Understanding, prioritization, and implementation.

Understanding Component Shortages

The first step to surviving the electronic component shortage of 2025 is to know what the causes are. Traditionally, shortages are caused by the following.

Electronic Component Shortage Causes:

- Limited material availability

- A limited number of manufacturers

- Lack of adequate geographic distribution of manufacturers

- Excessive demand

- Labor shortages

- Unexpected contingencies

- Adverse trade policies

All of the above can and do have a significant impact on the availability of electronic components. Similar to the global shortage in response to the COVID-19 pandemic, a major contributor to the 2025 shortage is governmental trade policy. While medical concerns were the motivation during the pandemic, tariffs are shaping up to be the major restriction to trade for 2025. Knowing how these policies affect you and your supply chain is critical to meeting your design and development demands and maximizing profitability.

Prioritization of Component Data

The underlying and often unheralded key to efficient PCB design and electronics product development is how well you utilize data. This includes industry data on component cost trends, new part introductions (NPIs), alternatives, and obsolescence. As accuracy is paramount for component data to be useful, you should lean on manufacturer resources, like datasheets, and trusted industry sources to ensure your ECAD models and actual components are in agreement.

Implementing Your Component Shortage Strategy

In addition to understanding how the electronic component shortage of 2025 is affecting your design and development process and prioritizing accurate data acquisition and utilization, it is important to leverage the most dedicated software tools available. Some advanced PCB design software tools do include component management functionality, but other EDA tools, including free and open-source platforms, may not possess the capabilities you need.

The best option for ensuring that you are able to make the best use of component data and information and optimize the integration of supply chain resilience actions is to partner with the industry’s leading resource for common and complex component CAD models, design information from major IC manufacturers, intelligent reference design and component library management software solutions, like DigiKey collaboration ULtraBOM.

If you’re looking for CAD models for common components or tools for surviving the electronic component shortage of 2025, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.