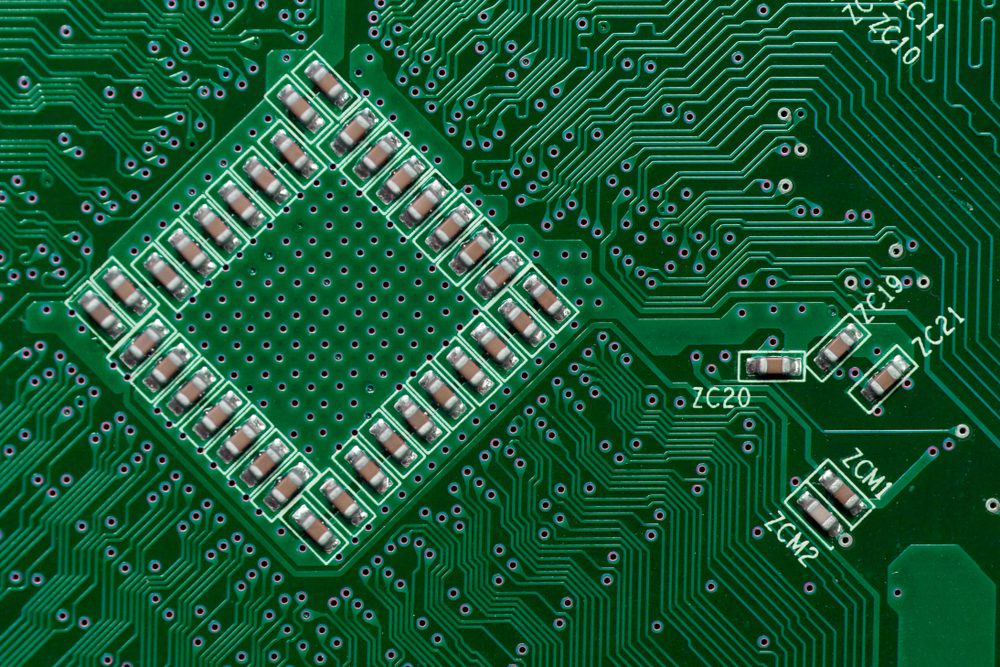

Ceramic capacitors on a circuit board

The Scottish philosopher Adam Smith, who is almost universally regarded as the father of economics, postulated that ‘consumption is the sole end and purpose of production.’ By this, he meant the need for a product will dictate how much of it is made. This forms the basis for what is commonly referred to as the law of supply and demand. Over the centuries, this tenet has proven to be quite accurate and has resulted in the proliferation of well-received or commonly used components such as multilayer ceramic chip (MLCC) capacitors, a preferred part for many PCBA designs.

Let’s take a look at why these capacitors are so popular and then explore a specific component, the CGA5L1X7R1H106K160AC by TDK Electronics.

Multilayer Ceramic Chip (MLCC) Capacitors

Capacitors are some of the most utilized passive components in electrical and/or electronic circuits. Capacitors have many uses, and chief among those are:

- Energy storage

Capacitors are often called batteries. This speaks to their most common usage, which is as energy storage devices.

- Coupling

Here, the DC signal component is blocked and only the AC component is passed through to the connected load or device.

- Decoupling

For decoupling, the capacitor isolates different parts of the circuit from each other. This is accomplished by removing noise and routing it to ground to prevent distortion effects.

- Filtering

Capacitive filters are used to remove unwanted frequencies from a signal. Often, these are higher order harmonics.

- Smoothing

By controlling the charge and discharge rates of a capacitor, it can be utilized as an effective smoothing device.

MLCC capacitors may be used for all of the above. Capacitors are classified in a number of ways, as shown below.

Capacitor Classifications

- Variable or fixed

- Dielectric material

- Surface mount or through-hole

- Polarized or non-polarized

MLCC capacitors are fixed value, ceramic dielectric, non-polarized, and may be SMDs or through-hole. These capacitors may be used for all of the above applications and are preferred when high-speed (or frequency) signaling processing is required. This popularity means many industries rely on a robust supply of MLCC capacitors to be available at all times. Unfortunately, that is currently not the case, as there has been a shortage of these components for the last few years. Yet, the future appears bright for common MLCC capacitors like TDK’s CGA5L1X7R1H106K160AC.

CGA5L1X7R1H106K160AC MLCC Capacitors

According to the TDK CGA series datasheet, the CGA5L1X7R1H106K160AC is a CGA series type 5 capacitor specifically designed for automotive applications. The part comes in a standard 1206 SMD package–3.20 mm (L) x 1.60 mm (W)–according to the Electronics Industries Association (EIA) code convention or 3216 according to the IPC SMD naming standard, IPC 7351. Internally, the component has the structure shown below.

Internal Structure

CGA5L1X7R1H106K160AC structure and materials

As shown above, the CGA5L1X7R1H106K160AC has an internal architecture consisting of alternating electrode-dielectric material layers. There are two classes of dielectric available for the CGA series capacitors:

1) Calcium zirconate

2) Barium titanate and the footprint contacts are comprised of tin, copper, and nickel

As a non-polarized component, the direction of placement or connection is not a factor when designing boards.

Parameters and Alternatives

The CGA5L1X7R1H106K160AC is the highest voltage rated (50V) capacitor in the CGA type 5 classification, as shown in the table below.

TDK CGA5L1X7R1H106K160AC parameters

The device also has a capacitance of 10µF, which is a common general application value, and a nominal operating range of -55 to +125 °C. These values make the component a good choice for high-speed applications for automotive systems.

PCBA Development With the CGA5L1X7R1H106K160AC

The CGA5L1X7R1H106K160AC is a commonly used MLCC capacitor that is recommended for automotive applications. This popularity means there is well-defined design data to help you incorporate the device into your PCBA development.

BOM Creation

Irrespective of whether you choose to design your schematic symbol and footprints from scratch or use previously developed libraries, it is important that your PCB layout matches the data and information in the BOM. For effective BOM creation, it is critical to ensure that an accurate MPN–based on the order number construction format shown in the figure below–is used; otherwise, you may experience delays in manufacturing.

Constructing the MPN

Due to the MLCC shortage, it is more important than ever that you seek out a reliable distributor for your component acquisition.

Design Options

The best way to ensure that your PCB layout is accurate is to incorporate accurate, manufacturer-vetted CAD models, as shown below.

CGA5L1X7R1H106K160AC CAD models

The CAD data shown above is readily available online for the CGA5L1X7R1H106K160AC MLCC capacitor.

Manufacturing Support

In order to help facilitate the manufacturing of your board, it is recommended that you utilize the extended datasheet. This document provides a more comprehensive evaluation of the CGA5L1X7R1H106K160AC, which includes recommendations for wave soldering, reflow soldering, and instructions on when rework is necessary. This and other manufacturing tips should be passed along to your CM.

If you’re looking for CAD models for common components, such as the TDK CGA5L1X7R1H106K160AC MLCC capacitor, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.