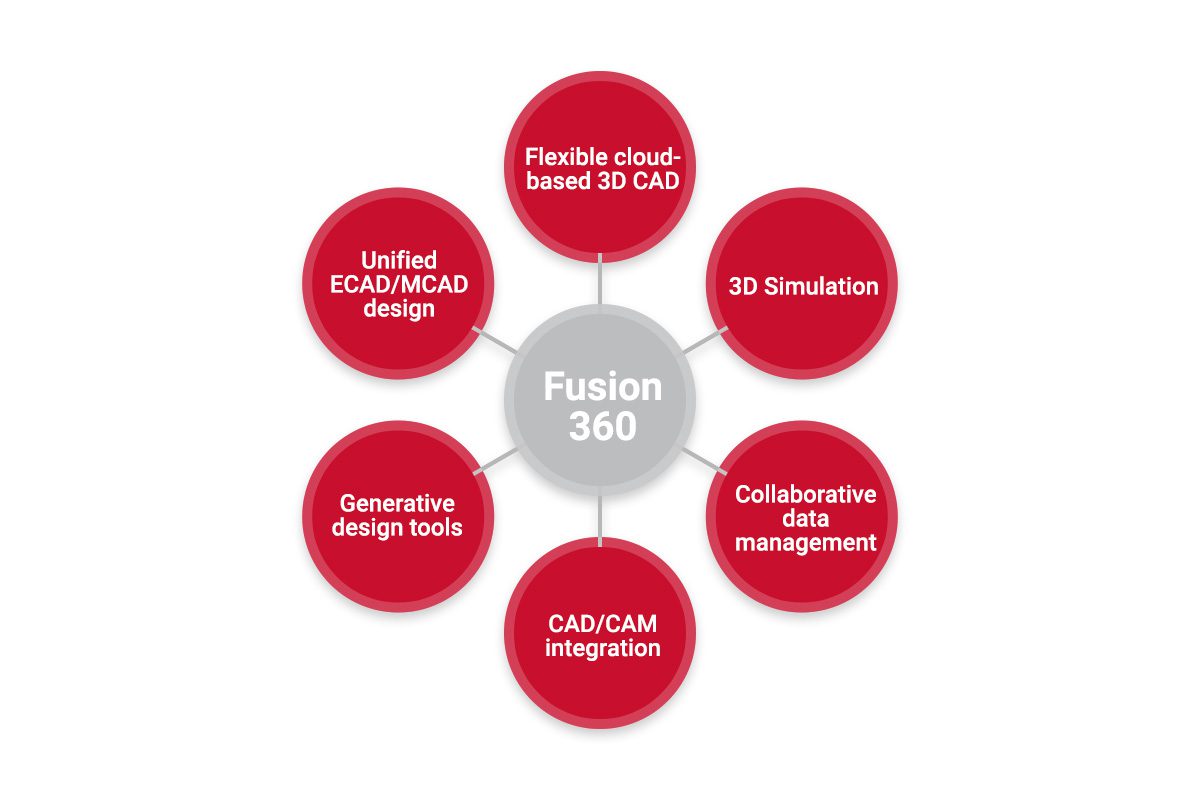

After decades of designing circuit boards in 2D, electronic engineers, and PCBA designers are increasingly leveraging the benefits of adopting a 3D perspective. Mechanical engineers have always utilized 3D drawings out of necessity. With electronics designers doing the same, ECAD/MCAD integration can be accomplished more efficiently.

Autodesk Inc. is accelerating this transformation with an ECAD and MCAD software platform. This development environment removes the need for design file conversions that can introduce errors or omit important details, promotes collaboration, saves time, and enables more streamlined design verification. With a simple EAGLE to Fusion 360 migration guide, you can quickly realize these benefits, even for previously designed boards.