1N4007 diode rectifier in a DO-41 package

When you abruptly cut power to an inductive load like a motor, solenoid, or relay coil, physics throws a tantrum. The collapsing magnetic field fights to keep current flowing, generating a massive voltage spike that can instantly fry your control circuitry. This is where the flyback diode (also known as a snubber, freewheeling, or catch diode) comes in handy. It provides a safe path for this “flyback” current to dissipate, protecting your sensitive transistors and microcontrollers.

While the concept is simple, selecting a flyback diode requires a bit more consideration than one might think. A mismatched diode can fail under stress or, worse, allow the very damage you’re trying to prevent. This guide breaks down the relay flyback diode selection process into clear, actionable steps to ensure your circuit continues to run.

| Quick Reference: Choosing a Flyback Diode by Application | ||

| Application Type | Recommended Diode Type | Key Selection Priority |

| General Relay & Solenoid | Standard Silicon Rectifier (e.g., 1N400x) | Voltage Headroom: Prioritize high reverse breakdown voltage (VR) over speed. |

| PWM Motor Control | Schottky Diode (e.g., 1N58xx) | Switching Speed: Requires fast recovery (trr) and low forward drop (VF) to reduce heat. |

| High-Speed Relay Release | Series Zener + Rectifier | Dissipation Rate: Increases clamping voltage to collapse the magnetic field faster. |

Key Parameters When Choosing a Flyback Diode

To select the right component, you first need to understand the specific stresses the diode will face. When the switch opens, the diode is no longer passive; it momentarily becomes the primary component of the circuit.

The three parameters you must evaluate are:

- Reverse Breakdown Voltage (VR): In normal operation (switch closed), the diode is reverse-biased. It must block the supply voltage without conducting.

- Forward Current Rating (IF): When the switch opens, the inductor forces current to flow through the diode. The diode must be able to handle this initial surge.

- Reverse Recovery Time (trr): This measures how quickly the diode switches from a conducting state back to a blocking state. This is critical for high-speed switching but less so for simple on/off applications.

Considerations for Selecting: Voltage, Current, Speed, and Power

Once you know the parameters, apply them to your specific circuit. Here is how to crunch the numbers for relay flyback diode selection and other inductive loads.

Voltage Ratings

The “golden rule” for voltage is headroom. When the load is powered, the diode sits in reverse bias across the power rail. If your supply is 24V, the diode “sees” 24V. However, real-world power supplies have noise, and inductive ringing can create spikes even before the main flyback event.

Selection Rule: Choose a diode with a Reverse Voltage (VR) rating of at least 1.5 to 2 times the supply voltage.

|

Current Ratings

Many designers assume the flyback current is small. In reality, an inductor acts like a flywheel—it resists changes in current. The moment the switch opens, the inductor drives current through the flyback diode at the exact same magnitude as the steady-state current flowing through the coil just before turn-off. While the current drops exponentially as energy dissipates, the diode must survive that initial peak. Most datasheet surge ratings (IFSM) are massive compared to continuous ratings, so if you meet the continuous requirement, the surge requirement is usually covered automatically.

Selection Rule: The diode’s Continuous Forward Current (IF) should be greater than or equal to the steady-state coil current.

|

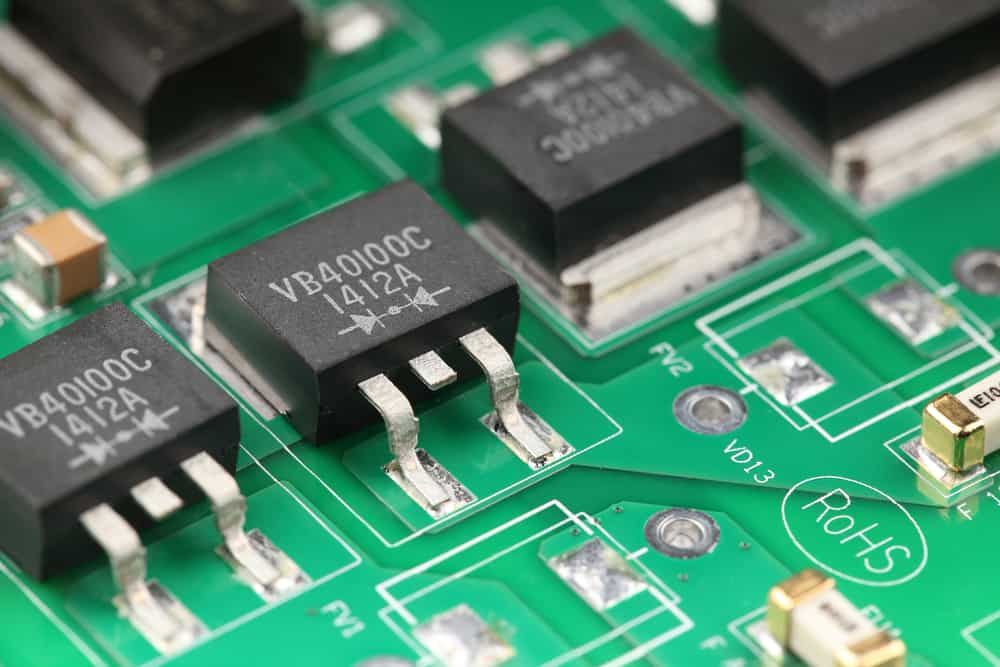

Speed: Standard vs. Schottky

Speed matters depending on your application.

- Relays and Solenoids (Low Frequency, < 1 kHz): For a relay that clicks on and off once every few seconds, speed is negligible. A standard silicon rectifier (like the 1N400x series) is robust and cost-effective.

- PWM and Motor Control (High Frequency, ≥ 1 kHz): If you are driving a motor with Pulse Width Modulation (PWM), the diode switches on and off thousands of times a second. A slow diode won’t block current fast enough when the transistor turns back on, leading to “shoot-through” current that heats up both the diode and the transistor.

| Recommendation: For PWM, use a Schottky diode. They have virtually zero reverse recovery time and a lower forward voltage drop, which improves efficiency. |

Schottky diodes and rectifiers mounted on a PCB

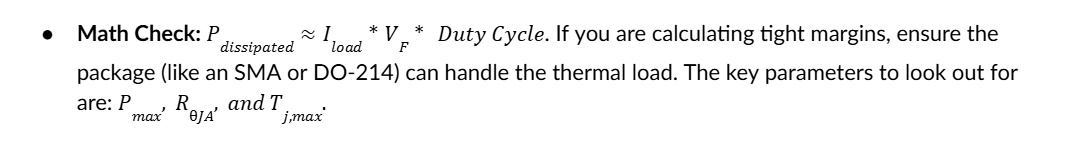

Power Dissipation

The energy stored in the inductor (E = 0.5 * L * I2) must be dissipated as heat in the diode and the coil resistance. For standard relays, the coil resistance dominates the energy burn, so the diode runs cool. However, in high-current motor applications, the diode’s forward voltage drop (VF) times the current creates significant heat.

Placement After Relay Flyback Diode Selection

You can pick the perfect diode, but if you place it poorly, you might as well not have one. The goal of the flyback diode is to contain the noisy, high-voltage loop to the smallest possible area.

- Proximity: Place the diode physically as close to the inductive load (the coil) as possible.

- Loop Area: The path from the coil, through the diode, and back to the coil is the “flyback loop.” If this loop is large, it acts like an antenna, broadcasting Electromagnetic Interference (EMI) into your nearby sensitive analog lines or microcontrollers.

- Wiring: If the relay is off-board (connected via long wires), place the diode directly across the relay terminals or at the connector on the PCB where the wires leave the board. Do not place it near the transistor if the load is feet away; the inductance of the long wires themselves can generate damaging spikes that the distant diode can’t clamp in time.

FAQ: Common Questions from the Engineering Community

Here are some answers to the most frequently asked questions when choosing a flyback diode.

- “Can I just use a 1N4007 for everything?”

Answer: For simple relay and solenoid circuits (< 1 kHz), yes. The 1N4007 handles 1A of continuous current and 1000V of reverse voltage, which covers 99% of relay applications. However, do not use it for high-frequency PWM motor driving; it is too slow and will cause your switching transistor to overheat.

- “Does the diode slow down my relay?”

Answer: Yes, it does. Because the diode circulates current, allowing the magnetic field to collapse slowly, the relay contact stays held in longer than it would naturally (sometimes by 10-20ms). If you need ultra-fast switching (to prevent contact arcing), consider adding a Zener diode in series with your flyback diode (anode-to-anode). This increases the clamping voltage, forcing the energy to dissipate much faster.

- “Should I put the diode near the MOSFET or the Relay?”

Answer: Ideally, near the Relay (Load). This keeps the high-current loop contained at the source of the noise. If you put the diode near the MOSFET and the relay is on a long cable, the cable’s own inductance can still cause voltage spikes at the transistor before the diode clamps them. If you can’t place the diode at the relay, put it at the PCB connector where the relay wires attach.

- “Why not use a Schottky diode for everything?”

Answer: You often can, but watch out for “Reverse Leakage Current.” Schottky diodes leak more current when reverse-biased, especially at high temperatures. In low-power, battery-operated circuits, this leakage might drain power unnecessarily. For general 12V/24V power switching, however, they are usually excellent choices due to their low forward voltage drop.

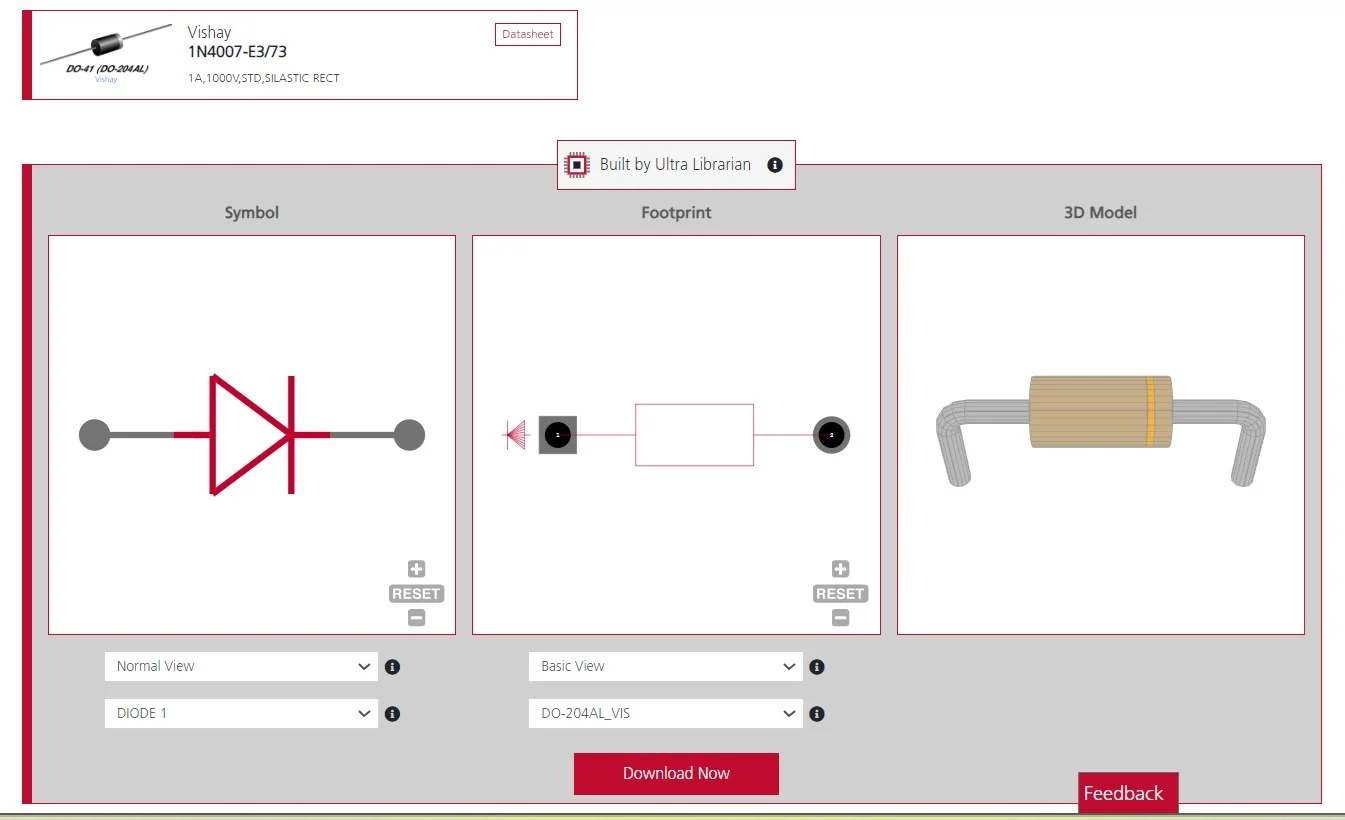

1N4007 footprint and CAD model from Ultra Librarian

Whether you are protecting a simple logic board or designing a complex industrial driver, having reliable footprints is non-negotiable. If you are currently choosing a flyback diode or need specific specs for relay flyback diode selection, Ultra Librarian helps by compiling all your sourcing and CAD information in one place. You can download verified 3D models and symbols compatible with popular ECAD applications and instantly view pricing from worldwide distributors, keeping your BOM consolidated and your project on track.

Working with Ultra Librarian sets your team up for success, ensuring streamlined and error-free design, production, and sourcing. Register today for free.