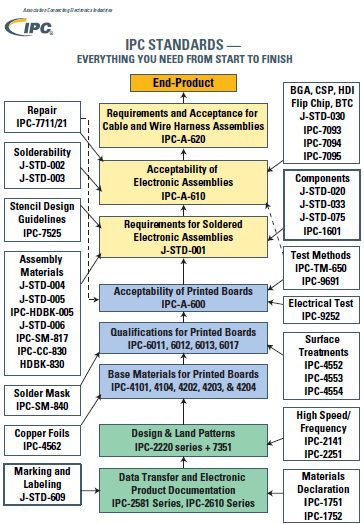

Designing circuit boards can be a very complex undertaking. The basic paradigm of selecting your parts, drawing the schematic, creating the PCB layout, and verifying your design is challenging in itself. Yet, every design must also adhere to rules and regulations. Failing to do so can make your board unbuildable, unmarketable, and unsafe.

It is important to follow good guidelines and implement best design practices to avoid these negative contingencies. However, knowing what PCB standards are helpful and which are mandatory is critical.

Passing your board’s PCB standards checklist