There are many factors to consider for component price comparison

The electronics industry is a dynamic and rapidly evolving landscape. For design engineers and procurement professionals, navigating this environment requires making informed decisions, especially when it comes to component price comparisons. It’s not just about finding the cheapest part; it’s about making choices that balance cost, performance, availability, and long-term viability. This isn’t a simple task, as a component’s perceived value often extends beyond its initial sticker price.Component Pricing: Beyond the Bill of Materials

When we discuss component pricing, we’re not just looking at a single figure. In electronics manufacturing, you’ll encounter a few distinct pricing types:- Book Price: This is the publicly listed price, typically tiered by purchase volume (e.g., 1-50 units, 50-100 units). It reflects standard market rates.

- Contract Price (Broken Price): Often used in competitive bids, this is a special price that frequently involves accounting adjustments from the manufacturer to the distributor, known as “debits,” to support specific projects.

- Direct Price: This is the cost quoted directly by the manufacturer to an Original Equipment Manufacturer (OEM), bypassing distributors altogether, usually for very large volumes or strategic partnerships.

| Pricing Factor | Description | Impact on Component Price |

|---|---|---|

| Raw Material Costs | The expense of foundational materials like copper, silicon, rare earth elements, or specific plastics. | A direct correlation. Fluctuations in global commodity markets directly affect manufacturing costs. |

| Research & Development | Investment in new technologies, fabrication processes, or product improvements. | Built into unit cost, particularly for advanced or proprietary components (e.g., ASICs, advanced microcontrollers). |

| Labor Costs | Expenses associated with manufacturing, assembly, and testing personnel. | Varies based on geographic manufacturing location and skill level required for complex processes (e.g., wafer fabrication). |

| Exchange Rates | Fluctuations in currency valuations between countries involved in the supply chain. | Impacts import and export costs for materials and finished goods. |

| Market Competition | The presence and intensity of competing manufacturers and product alternatives. | Can drive prices down as companies vie for market share, but may also lead to strategic pricing tiers or bundled offerings. |

| Logistics & Supply Chain | Costs related to shipping, warehousing, distribution, and inventory management. | Adds to the final delivered cost, especially for globally sourced components. |

Beyond Simple Cost: Performance, Form Factor, and Reliability

It’s easy to get fixated on the lowest possible unit cost, especially when scaling production. However, focusing on price as the sole driver in component selection is often a false economy. The real cost of a “cheap” part can quickly skyrocket if it leads to:- Subpar Performance: Components that barely meet minimum specifications might fail prematurely or cause system instability. This can lead to increased warranty claims, field failures, and reputational damage.

- Fitment Issues: An improperly sized package or an unusual pin-out can create significant challenges on a PCB layout, necessitating expensive board revisions. Early access to 2D symbols, footprints, and 3D CAD models, such as those available through Ultra Librarian, enables designers to visualize how a component integrates into their layout, thereby preventing these headaches.

- Supply Chain Disruptions: A low-cost component from a single, unreliable vendor can leave you critically short if stock vanishes or lead times stretch indefinitely, halting production.

- Regulatory Non-Compliance: Skimping on costs may inadvertently lead to the selection of parts that don’t meet industry standards, such as RoHS (Restriction of Hazardous Substances) or REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), risking legal repercussions and market access issues.

Digital Tools for Component Price Comparison

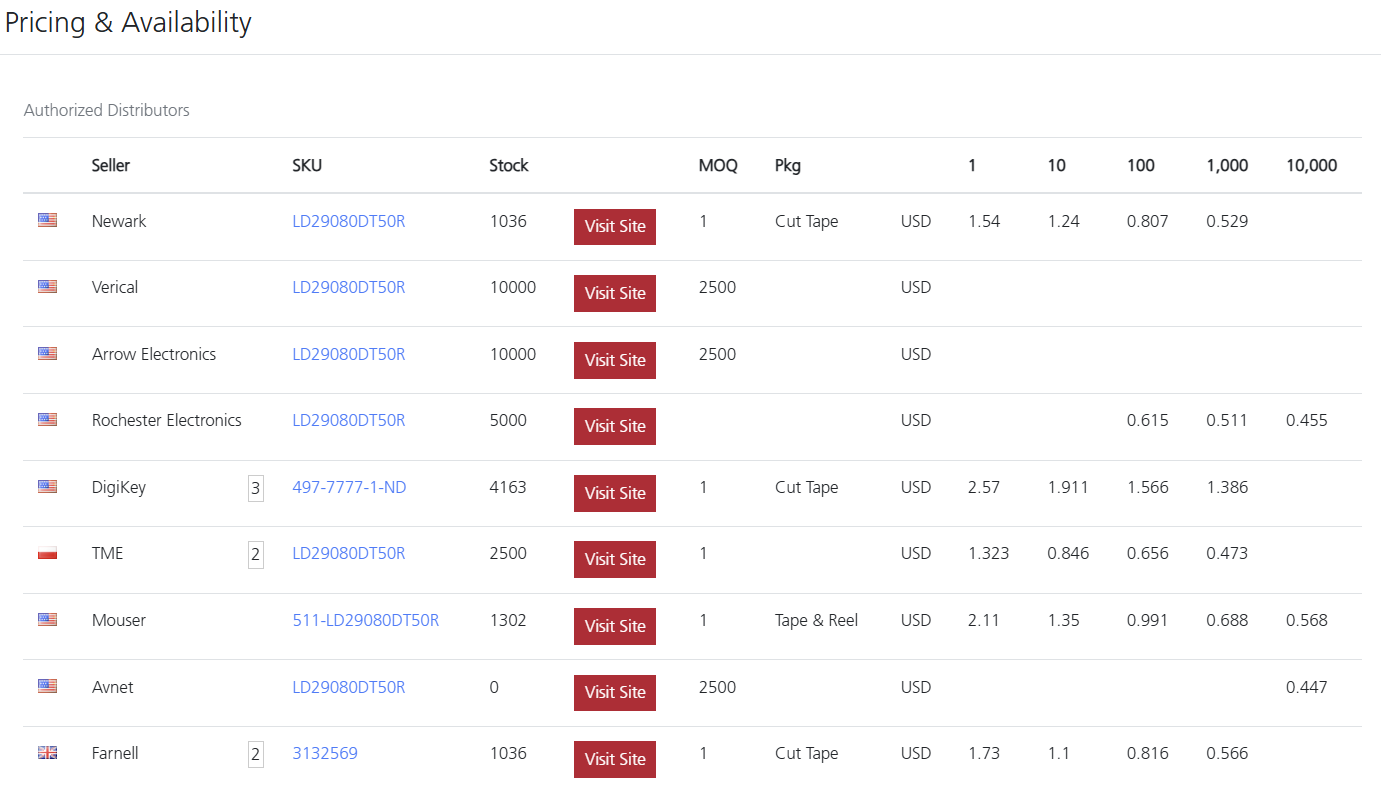

Pricing & Availability Data on Ultra Librarian

Manually sifting through individual distributor websites to compare component prices, stock levels, and technical specifications is a cumbersome task. This is where specialized electronic component search engines truly shine. Unlike general search engines or individual distributor sites, these platforms aggregate vast amounts of data from across the supply chain, providing a comprehensive and real-time view. Platforms like Ultra Librarian compile the most important information, streamlining the component selection process.Traditional Component Data Acquisition vs. Modern Digital Platforms

| Feature/Method | Traditional Manual Search (Individual Distributor Websites) | Modern Digital Tools (Aggregated Search Engines) |

|---|---|---|

| Price Data |

|

|

| Stock & Lead Times |

|

|

| Technical Specs |

|

|

| CAD Models |

|

|

| Obsolescence Data |

|

|

| Compliance Data |

|

|

Integrating Digital Tools for Proactive Design and Library Management

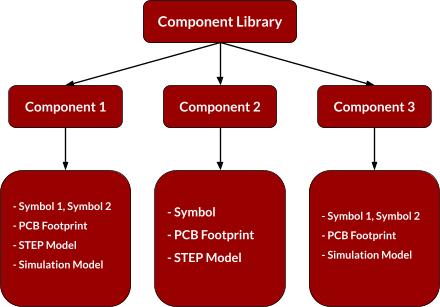

Advanced digital tools are increasingly integrating supply chain intelligence directly into Electronic Design Automation (EDA) workflows, allowing engineers to proactively assess component risk, availability, and compliance during the design phase. This approach transforms component selection into an informed process from schematic capture onward. The comprehensive data gathered, encompassing pricing, availability, and technical specifications, is foundational for building and maintaining PCB component libraries with verified symbols, footprints, and 3D models. Platforms like Ultra Librarian facilitate this by providing high-quality CAD models, significantly reducing design time and errors. This rigorous component selection and library curation, driven by thorough component price comparison, directly contributes to the quality needed for effective PCB component library comparison, emphasizing the value of unified, reliable component data.

Structure of a typical PCB component library

If you’re looking for CAD models for common components or need fast, accurate component price comparison data, Ultra Librarian brings everything together in one place. Our platform gathers verified symbols, footprints, and 3D models for popular ECAD applications, paired with real-time sourcing insight from worldwide distributors. That means you can review pricing tiers, check inventory, confirm compliance, and pull CAD data without bouncing across a dozen tabs. Working with Ultra Librarian sets your team up for success, ensuring streamlined and error-free design, production, and sourcing. Register today for free.