Engineering team exploring options for managing custom PCB design cost.

Whether an experienced engineer or new to laying out circuit boards, most of us would love the opportunity to design the perfect circuit board unencumbered by petty concerns like how much it costs. In reality, of course, there are always project constraints and restrictions, including cost. In fact, engineers need to be aware of how trends, like component costs, impact their projects.

This concern is especially pertinent today with the number of uncertainties surrounding electronics development. For example, there has never been as much uncertainty about component and material availability as supply chain disruption issues continue to be a major concern. Consequently, it is critical to know and effectively execute techniques for managing your custom PCB design cost.

PCB Design Cost Management Techniques

The competitiveness of the electronics industry demands that all stakeholders in the development process strive for maximum effectiveness and efficiency. The brunt of this burden falls on the engineers and PCB designers, who create and define the parts and materials required for the product. Understanding cost management techniques, as described below, is essential for satisfying this mandate.

| CUSTOM PCB DESIGN COST MANAGEMENT TECHNIQUES | |

| Techniques | Importance |

| Simplify the design | Complex design requirements, like meeting board density requirements to adhere to installation constraints, are typically more costly. |

| Select lower-cost component alternatives | With deference to design quality and performance, in some cases, lower-cost component alternatives may be viable substitutes. |

| Choose standard component packages | Standard component packages , especially for ICs, are easier to implement as accurate schematic symbols, footprints, and 3D CAD models are readily available. |

| Use standard board sizes | For most PCB programs, including open-source platforms , designing boards with standard sizes and shapes is simpler and faster. Additionally, these are the most cost-effective PCBs to manufacture. |

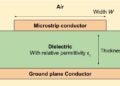

| Choose common materials | In some cases, general circuit board materials , such as FR-4, may be adequate, as opposed to special materials that may be more costly. |

| Prioritize component placement and efficient routing | Component placement and trace routing are inextricably linked and impactful. Failing to prioritize the optimization of both will result in longer design periods and possibly costly redesigns. |

| Create a comprehensive BOM | The BOM is one of the most important documents. Failing to ensure your BOM is accurate and complete will likely result in additional design time and increased overall development costs. |

| Incorporate your CM’s DFM and DFA guidelines | To minimize overall PCB development costs, it is imperative to follow the DFM and DFA rules and guidelines for your CM’s equipment and processes. |

| Opt for component kitting, if available | Kitting or procuring component sets from a single source minimizes the time needed for part research, supports efficient inventory management, and helps lower shipping expenses. |

For some markets, such as the European Union, where RoHS and REACH compliance is required, the cost benefits of implementing the techniques above must be balanced against environmental, regulatory, or other sustainability concerns. However, in all cases, adopting and following an effective PCB design cost management strategy is necessary.

Effective Custom PCB Design Cost Management

Designing electronic circuit boards should always be guided by a thrust to maximize engineering workflow efficiency. Of the many aspects to consider for adherence to this mandate, managing custom design costs is high on the list. By instituting the following guidelines into your design process, this goal is readily attainable.

✅ Employ a reliable and comprehensive component search tool. ✅ Build and use a CAD library that best aligns with your current and future design needs. ✅ Utilize the best inventory management tool for your design project requirements. ✅ Apply design verification tools to ensure operational and manufacturing needs are met. ✅ Embrace collaboration with your CM to ensure the manufacturability of your design. |

If you can check the box for the guidelines above, then your custom PCB design cost will be well-managed. Critical to this success is your component selection process, which must include awareness of factors that affect pricing, include real-time component data, and rely on trusted sourcing resources.

If you’re looking for CAD models for common components or important information to help you manage custom PCB design costs, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.