Electronic component semiconductor silicon wafer

It is indisputable that the invention of the transistor opened the door for the current technological revolution. Today, it is becoming increasingly difficult to find products that do not leverage electronics to enhance capabilities and functionality. More often than not, these products and systems are driven by circuit boards that include transistors or other semiconductors. The importance of semiconductors is evidenced by the success and growth of their manufacturers. These companies transform silicon, germanium, gallium-arsenide, and other semiconductor materials into the most commonly used PCB semiconductors: diodes, transistors, and integrated circuits. By understanding their key attributes and following good design guidelines, you can best utilize electronic components semiconductors in your circuit board and/or product design.Common Electronic Component Semiconductors

Semiconductive materials fall somewhere between insulators, which are highly resistive to current flow, and conductors, which are minimally resistant. Other than passive parts that only dissipate power, like resistors and capacitors, discrete and active semiconductors are the most commonly used components in electronic circuits. Here are the attributes of the most common electronic component semiconductors:| Electronic Components Semiconductor Attributes | |||

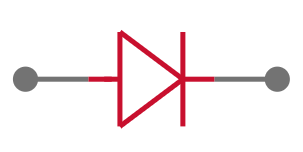

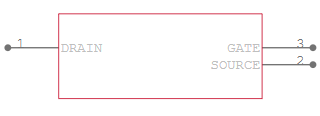

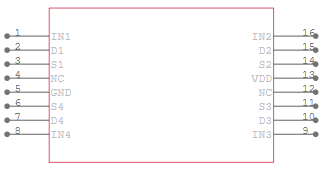

| Attributes | Diode | Transistor | Integrated Circuit (IC) |

| Common Types |

|

|

|

| Typical Applications | Rectifiers, Voltage regulators, Demodulators, Switches | Amplifiers, Switches | Microprocessors (MPUs), Control circuitry, signal processing, component arrays, complex circuits |

| Examples | |||

| Component | 1N5230B Zener Diode | 2N5459 JFET Transistor | ADG811YRUZ Analog IC |

| Schematic Symbol |  |

|

|

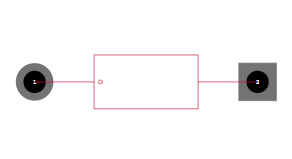

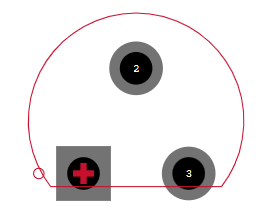

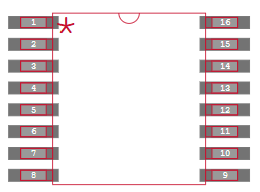

| PCB Footprint |  |

|

|

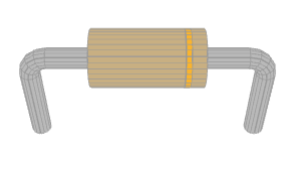

| 3D Model* |  |

|

|

*3D model depends on package selection.

As alluded to by the examples above, semiconductor components are available as surface mount and through-hole technology devices. Additionally, IC package types for these components come in all shapes and sizes. These dimensional variations are but one of the many considerations when designing circuit boards with semiconductor components.

Semiconductor Design Guidelines

Apart from very basic cases, developing printed circuit boards consists of three distinct but equally dependent stages: design, build, and test. The success of this cyclic D⇒B⇒T process and the quality of the resulting board are significantly defined by the choices made and practices followed during design. It is important to follow best practices for component selection, schematic symbol and footprint creation and usage, component placement, and PCB layout design. For semiconductor board design, these practices can be summarized as choosing the right component, verifying performance, and preparing for manufacturing.

Choosing the Right Package

As mentioned previously, there are multiple package options when choosing the best semiconductor for your design. For example, dual and quad-package semiconductor components may be a good option if ample space is available and/or individual device functions are implemented within the same sub-circuitry. By contrast, the benefit of these package types can be negated by extensive routing requirements when subcircuits are separated in the layout. This latter case can have a significant impact on high-speed design, where best practices dictate that short routes or matching impedances are required, as is the case in differential trace routing.

Verifying Performance

The vast number of semiconductor component options is both an asset and a disadvantage. It is common that multiple components are able to meet your performance objectives, which makes vetting candidate components even more important. The best means of ensuring performance is to source from leading distributors, leverage datasheets, and only use manufacturer-verified CAD models and other information. It is also a good idea to apply simulation to verify performance and avoid having to make costly changes later in the process.

Preparing for Manufacturing

Effective CAD library management is also important to help facilitate efficient manufacturing. This is especially important during the development of prototypes, as several D⇒B⇒T iterations are typically required before a production-ready design is achieved.

Optimizing Your Semiconductor PCB Design Process

The best PCB designs are products of applying the best practices and using the best tools. For semiconductor board design, this includes understanding the unique attributes of semiconductor components, relying on an industry-leading component search tool, and following the best design practices. Using this paradigm as a guide will help achieve an optimal design and development process for your electronic components semiconductor project.

If you’re looking for CAD models for common components or guidance on how to best design PCBs with electronic component semiconductors, Ultra Librarian helps by compiling all your sourcing and CAD information in one place.

Working with Ultra Librarian sets up your team for success to ensure streamlined and error-free design, production, and sourcing. Register today for free.